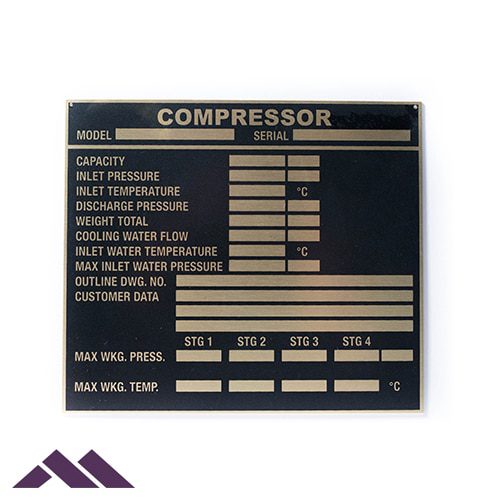

Metal Marker provides both laser etching and chemical etching services for various metal labels.

Metal Marker’s award winning quality and delivery and knowledgeable customer service representatives makes Metal Marker your source for etching. Our customer service representatives can work with you to develop the solution to best meet your needs. Please contact one of our customer service representatives to obtain additional information or a quote for etching.

What is Etching?

There are two ways that the etching process can be done. Laser etching might be the first that comes to mind. As you can imagine, a high powered laser is used to remove material to create an image or design. It can handle any design or data that you desire.

Another way to etch is by using chemicals. Essentially, this is done through a chemical process which dissolves the metal. The chemicals are carefully utilized to only burn the area which will create the design or information as specified.

Etching is used in a wide range of applications, for many different industries. Industrial companies use them for many purposes. Custom nameplates or signage are just two examples. They are also used in non-industrial applications.

Durability

Etched metal tags fall right about in the middle of the durability range for metal tags. They typically last around 5 – 10 years. They are not nearly as durable as some processes such as MetalPhoto, engraving, or embossing which all last 20+ years. However, they are much more resilient than decals or screen printing.

Since the design is dissolved or burned into the metal, it has greater lasting ability than ink. However, it is not the same amount of resilience that you get with a stamped or embossed metal. Over time, the metal will wear and the information will become less legible.

If you choose to add ink using the “etch and fill” process, durability of the printing should be considered. The ink will not last as long as the etching itself. It will be prone to wear and tear much faster.

Customization

One of the biggest strengths of etching is the amount of customization. Since the design is embedded using a laser or chemicals, you are freed up from some of the restrictions imposed by other processes. This offers major flexibility in your design choices.

Another option is serialized and/or variable data. However, this feature comes at a significant cost due to the increased time and difficulty of labor. Other solutions such as MetalPhoto also share this capability without impacting cost.

Any shape, size, and thickness is available. If you need a certain corner shape, that’s doable. Holes can be made of various sizes and patterns. They can be used to place the tag on a flat surface or hang using a wire. If you need to use it on a flat surface there are other options as well.

Instead of using holes for placement, adhesive backing can be added for a peel and stick application. This makes attaching your tags very quick and easy. There are many different adhesives each with their own strengths and properties to fit a wide range of situations. Whether you need industrial grade adhesive that can hold incredibly strong, or a cheaper low-grade adhesive that gets the job done, your requirements can be met.

Etch and Fill

One of the unique features of etched tags is the option for etch and fill. After the design is etched, it can then be filled in with a color of your choosing. This creates the opportunity for increased customization. This is one key element that separates etching from other processes.

Your text or design can be any color. The background will remain the natural color of the metal substrate. This allows for etched metal tags to really stand out.

Keep in mind that the durability of the tags does not include the coloring. It is significantly more prone to wear and tear than the actual etching itself. While the color may fade or eventually be removed through wear, the etching will stay for a longer period of time

Materials

-

Aluminum

-

Brass

-

Stainless Steel

-

Cold Rolled Steel

Industries

-

Aerospace

-

Transportation

-

Energy

-

Defense

-

And many more!

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.