When you first think about metal tags, you probably think of aluminum or stainless steel plates. Yet, there are other material options as well. One of the best material options for custom identification is brass. Custom brass tags are extremely useful as an identification solution.

Brass tags are also a popular choice for businesses that want to identify their property with a name or logo. Brass is a durable material that can withstand the wear and tear of everyday use. In addition, brass tags can be customized to include any text or design you choose. If you’re looking for a unique way to mark your business property, brass tags are the perfect option.

What is Brass?

Brass is a unique material, which has a plethora of uses in just as many industries. It is a metal alloy, composed of zinc and copper. This specialized makeup gives brass a shiny, gold-like appearance.

While the substrate may start off shiny, after it is used in tough conditions it develops a patina-like finish. This is actually a preferential feature by many, as this worn look is often considered vintage. If you are looking for a material with a worn, rustic aesthetic, brass is the perfect option.

Durability

In addition to having a stand-out appearance, brass is also a very durable metal. This makes it useful in industrial environments from manufacturing facilities and construction sites to energy plants and mines.

The material is also resistant to water and corrosion. This lends itself to uses that expose the metal to water or other light chemicals.

One thing to be aware of is that brass is considered a softer metal than comparable materials. This can be a benefit or hindrance depending on your exact specifications or requirements.

Other Metal Properties

Not only is brass durable, but it also exhibits other signature properties. These features are often key in selecting brass as a material of choice for a given industry.

For example, brass is a non-ferrous metal. This means that the metal is not magnetic. While that may not seem like it has significance, it can be incredibly important for specific usage.

Certain industries require working with non-ferrous metals for safety reasons. The mining industry, for example, typically elects to use brass for their identification needs to avoid potential risks.

Brass also provides a low friction metal surface. This leads to heavy usage in items such as instruments, gears, bearings, and more.

Plus, it lends itself to applications that need to prevent generating a spark. Since the material is low friction, it is much safer to use in environments that would be especially susceptible to the potential of a fire.

What are Brass Tags Used For?

Brass tags are a valuable asset to any business. Not only do they add a touch of elegance and class, but they also serve as a means of identification and protection.

Brass tags and nameplates are used for an enormous range of applications. Their high durability, versatility, and special metal properties make them an excellent candidate for many industries.

Some of the most common industries which use these identification tags are the plumbing and electrical industries. This is due in part to the low friction property, as well as the resistance to corrosion and water.

Another common use for brass is metal cable ties. These ties wrap around pipes or cables, allowing for easy attachment and clear identification.

In addition, some applications such as furniture nameplates turn to brass specifically due to the vintage gold appearance.

While these are many of the most common applications, this is in no means a limit to the possibilities. Industries big and small find a very large range of uses for brass identification that suits them.

Processes for Brass Tags

Brass is a versatile material, and as such can be marked with several different processes. Each has its own set of pros and cons. The best process is the one that fits your application the best and is suitable for your customers.

Etching

Brass nameplates may be marked using the etching process. This includes both laser and chemical etching.

Laser etching uses a high-powered laser to wear away the material, while chemical etching accomplishes this using specialized chemicals. Both methods create a moderately durable custom design in the metal.

After the design is etched, colored ink can be put in. This is often referred to as etch and fill. By adding a bit of color, your tag designs can stand out. The only drawback is lack of durability, as this ink will wear when exposed to tough conditions.

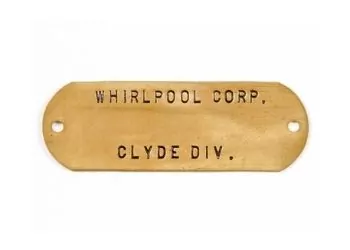

Stamping

For a more permanent solution, brass tags are frequently stamped. This process is very straightforward, as a custom stamp is pressed into the metal blank to leave an indented design.

This indented design will not simply scratch off. It will last as long as the metal material does.

Embossing

Sometimes you need maximum durability. It’s hard to go wrong with the embossing process. By using a male & female die set, the brass is pressed to form raised metal characters.

These characters are incredibly durable. In addition, they are still going to be legible even after the nameplate gets covered in grit, grime, and dirt. Even paint can’t keep the letters or numbers from being readable.

Get Custom Brass Tags Today

Brass tags are an incredibly versatile solution. Their golden appearance gives them a unique look, while durability makes them ready to tackle tough industrial conditions. Whether your tags are for marking an industrial valve, or just to mark your custom furniture, brass might be the perfect choice for you.

Our brass tags are made with the highest quality materials and can be customized to suit your needs. To see what we have available for you, please contact us today!

REQUEST A FREE QUOTE

FILL OUT THE FORM, OR GIVE US A CALL:

Let us create a custom solution tailored to your unique needs and challenges.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.