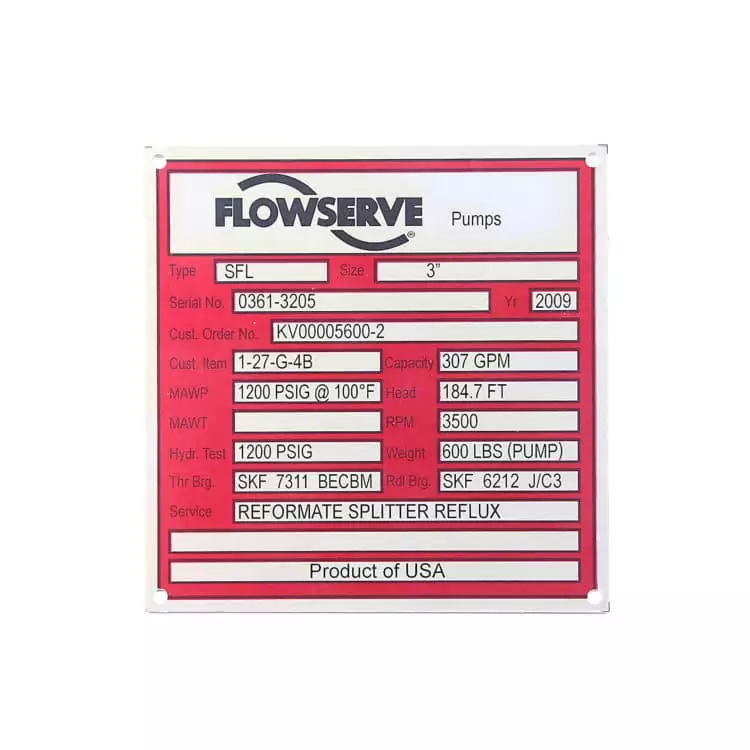

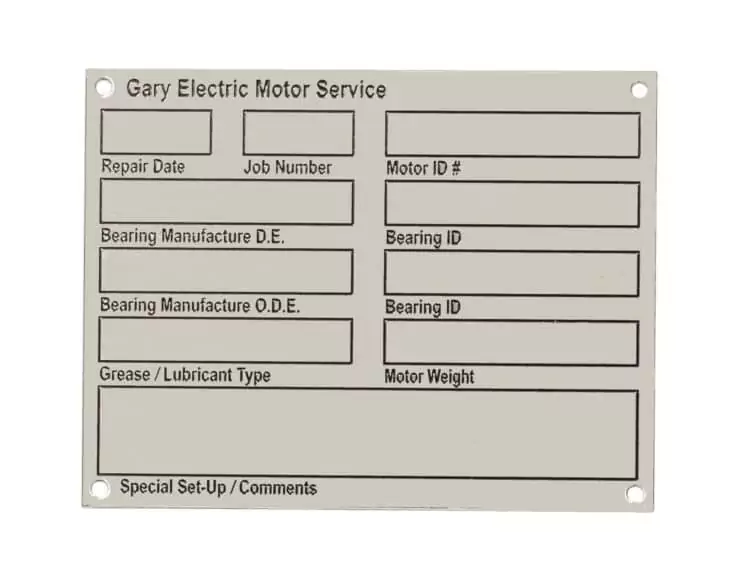

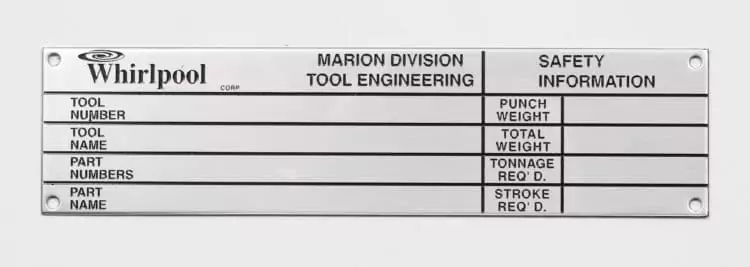

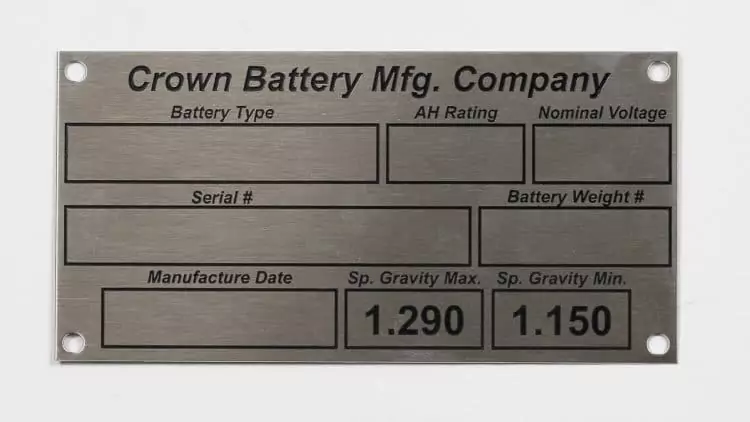

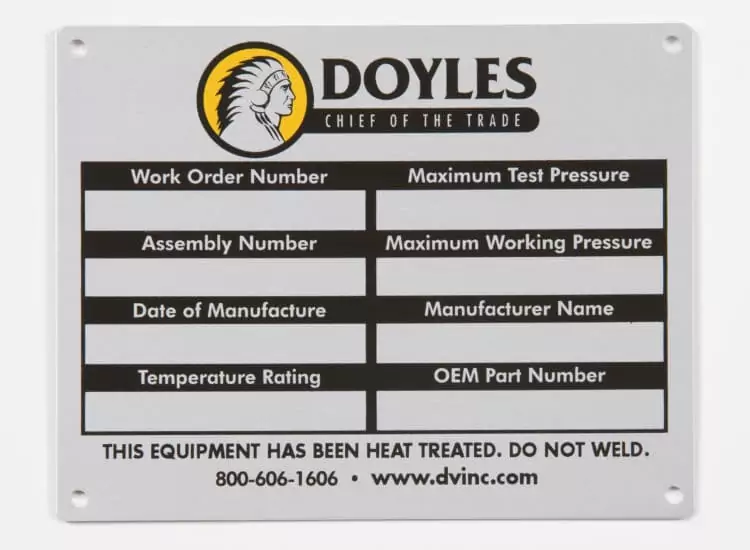

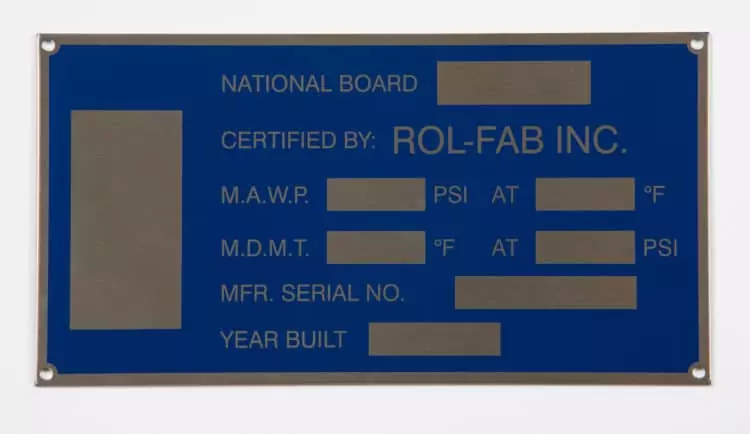

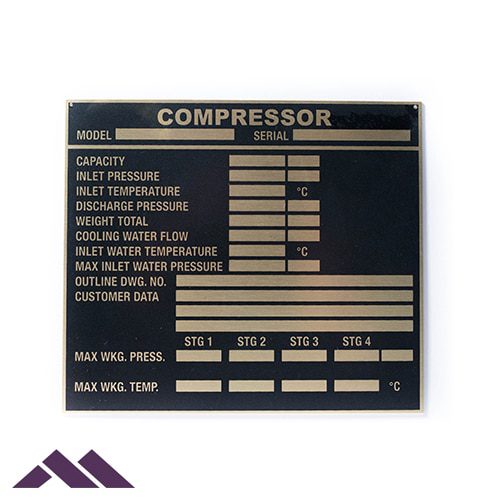

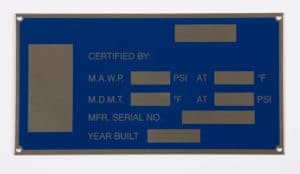

Our custom data plates are built exactly to your specifications. These highly durable identification plates are used in a wide range of applications.

Designed for industrial use, they are affixed to equipment, machines, tools, and more. Whether it’s providing the date of manufacture specifications, equipment serial number, safety warnings, or additional useful information.

At Metal Marker, our focus is on high-quality custom identification solutions. We provide you with the peace of mind that you’re getting the right product for your needs.

Not sure what ID solution is right for you? Have questions?

Our nameplate customer service representatives are highly knowledgeable and ready to help guide you to the perfect solution.

Simply fill out our contact form or give us a call at (800) 428-0095

What Are Data Plates Used For?

Custom metal data plates are used for a wide range of purposes across many industries.

Manufacturers affix plates to their equipment to provide accurate specs and information to operators. Construction machinery such as forklifts is marked with weight tolerances and guidelines. Shipping containers are marked with mandated info for international commerce. The list goes on and on.

Applications

Organizations across the globe utilize custom data plates for a variety of purposes. The following information depicts a few examples of how Metal Marker’s data plates have been used:

- Manufacturing: Manufacturing plants and factories label their machinery and equipment to easily depict the model number and ensure proper use. The nameplates can also be used for model designation for easy equipment identification.

- Construction: Construction equipment and tools need to be labeled with pertinent safety information and tolerances. Furthermore, when manufactured home and mobile home data needs to identify they were built in compliance with HUD manufactured home construction and safety standards. Data plates are a perfect way to present the performance verification certificate.

- Aerospace: Aircraft data plates can be attached to the fuselage of the plane to depict proper ISO and other FAA compliance.

Durability

What makes for a good new data plate? One that lasts as long as you need it to.

Many work environments include chemical exposure, inclement weather, wear and tear, and everything in between. If your metal tag is no longer legible after a few weeks, it isn’t the right fit.

Our high-quality plate solutions can last upwards of 20+ years in the harshest environments, if necessary.

Knowing your application is half the battle. From there we can help you choose the material and process which best fits your needs.

Materials

Metal data plates for the industry are produced in several different substrates to fit various specifications and durability requirements.

Aluminum

One of the most popular options, aluminum provides a highly durable solution with a ton of versatility. The material is also very lightweight, allowing it to be used in industries such as aerospace without issue.

The anodization process improves the corrosive resistance of the material, as well as allows for the addition of color to the plate.

Stainless Steel

One of the absolute sturdiest materials used for data marking is stainless steel. This metal substrate is preferred for its ability to withstand many years of wear.

Keep in mind, stainless plates are only as durable as the process you select. For example, ink printed on top of stainless steel is not going to last decades like the material itself will.

Brass

As mentioned, every application is different. Certain industries need certain materials. Brass is a great example of a material that is less commonly used but is the perfect solution for specific applications.

Sometimes it’s the preference for a vintage appearance of a furniture plate or a type of valve that always uses brass marking tags. If it fits your needs, brass provides a durable and suitable solution.

Industries

Custom metal data plates are used by a wide range of industries. From shipyards to manufacturing plants, most industrial organizations rely on identification plates. Some industry examples include:

- Construction

- Energy

- Equipment Manufacturers

- Government (Federal, State and Local)

- Oil & Gas

- Telecommunications

Processes

Photo Anodized

The photo anodization process embeds a custom design directly into layers of special anodized aluminum material. By keeping the design below the surface, there is no ink or raised surface to wear away.

This process is recommended for many industrial applications as it is incredibly durable. Photo anodized data plates are rated for 20+ years outdoors.

In addition, the options for this process are nearly unlimited. Any design, text, image, or even barcode can be added. Solid background color can also be added to create a standout appearance.

Etched

One of the most commonly requested processes is etching. Etched plates are produced using either a laser or chemical process, which removes only the area of the material required to create a design.

This process is durable, and typically marks information in an easily legible way.

Color can also be added using the etch and fill process, although be aware that the color will have lessened durability.

Screen Printed

Need your design to include custom colors? Screen printing might be your best option. This process involves pressing ink through a screen directly onto the metal substrate.

This provides the benefit of custom full-color designs. The drawback to topical ink printing is that the designs will wear off when exposed to harsh conditions.

Customization

Our metal data plates are fully customizable with any information.

This allows for virtually unlimited customization. We can add nearly anything you can imagine, including images, designs, logos, and more.

Make your plates stand out, or just make sure they fit every requirement – entirely up to you.

REQUEST A FREE QUOTE

FILL OUT THE FORM, OR GIVE US A CALL:

Let us create a custom solution tailored to your unique needs and challenges.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.