Railroads are incredibly important to trade and commerce around the world. What we often forget is the engineering that makes them possible. Superelevation measurements make sure that proper safety standards are followed by utilizing a railroad tag.

What is Superelevation?

Think about an oval shaped racetrack. When the race drivers get to the end to make their turn, the track becomes heavily sloped. If the track was flat, the high speed vehicles would not be able to make the turn.

When these drivers are making the turn, they are subjecting the vehicle to centrifugal force. Without the slope, they would skid off the side of the road due to this strong outward force.

This same concept applies to locomotives. Trains are large, heavy, and fast moving vehicles. When they attempt to round a corner, they exude a tremendous amount of force onto the railroad tracks.

In order to counteract this force, railroad tracks are strategically positioned to create a slope – just like the race track.

This slope is created by raising the outer rail higher than the inner rail on a curve. This difference in height is called the superelevation. It is sometimes referred to as a railroad cant.

The inner rail is used as a reference point, and is typically maintained at its original level. This rail is often called the gradient rail. https://en.wikipedia.org/wiki/Cant_(road/rail)

What are Superelevation Tags Used For?

In order for railroad engineers to correctly inspect and repair tracks they need to know the correct elevation between the inner and outer rails. This is where superelevation tags come into use.

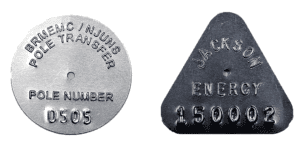

These permanent metal identification tags are affixed to the tracks to provide clear and accurate information. This often will be as simple as a measurement number. Typically, superelevation is measured in increments of ¼ inches starting at a base of zero. The tags are positioned in ascending order, making them easy to follow.

Safety

Trains are vital to transportation of goods and materials. Making sure that the shipments make it to their destination as quickly and efficiently as possible is important. However, safety is even more important.

Train derailments can damage property, and endanger lives. There is no room for mistakes. The tracks need to be setup, measured, and maintained to standards.

Tags also make inspecting and servicing tracks much simpler. Having quick access to the measurements makes it much easier to spot errors and make adjustments.

Tags Made for the Railroad

Durability

For a railroad tag to be used on tracks, it must be incredibly durable. Just like the tracks themselves, the track tags will be exposed to tough environments. Weather resistance is an absolute must as these nameplates are open to all weather conditions.

In addition, superelevation tags are also in close proximity to trains going by constantly. This creates jarring vibrations, high wind speeds, dust, and debris.

Processes

Stamping

Stamping is the most common process used for super elevation tags. It uses a custom made stamp to press the information into the tag.

These indented characters are very strong, and will not be scraped or scratched away from wear. The numbers are easy to read, and are suitable for the railroad application.

Embossing

Another viable option is the embossing process. This process is also made to withstand tough industrial conditions. Embossing creates upward raised designs in the material.

These raised characters are extremely durable and make visibility very easy. They even stand out when the tags get covered by dust or debris, making them useful for a superelevation identification solution.

Materials

Anodized Aluminum

Anodized aluminum is one of the most versatile materials using in identification tags. It is very durable, including resistance to corrosion, weather, and wear. Yet even with high durability it remains very lightweight.

Brass

Brass material is often used for piping and valves, but is suitable for other applications as well. These nameplates are water resistant and durable, making them suitable for outdoor applications such as rail road.

Stainless Steel

Stainless steel is extremely durable. Stainless steel tags provide long lasting identification in even the absolute toughest environments. Since your rail road tags are going to be exposed to harsh conditions, stainless steel is a great material option.

Wrap-Up

Metal superelevation tags mean the difference between an accurate measurement and a potential safety hazard. Their ability to withstand the heavy wear and tear of outdoor use makes them the perfect solution for the railroad industry.