Dot peen marking (also commonly referred to as dot pin marking) is a unique process that differs from other marking techniques.

It does not use a high-powered laser, a chemical process, or a stamping die. Instead, dot pinning utilizes a specialized machine with an impacting stylus. This stylus rapidly indents dot shaped marks in a metal surface. It can be used to imprint a custom design made entirely out of these dots.

Dot pinning is able to create both letters and numbers, as well as simple logos and even 2D data matrix codes.

What Can it be Used to Mark?

When you think of identification in an industrial environment, your first thought would be a metal tag or nameplate attached onto a machine.

This process is typically used in a slightly different manner. Since it doesn’t have the same restrictions as other processes, the information can be embedded directly onto the item itself.

This includes machinery, tools, equipment, and more. Anything made with metal material thick enough to withstand the impacts can be dot pinned.

Using the dot peen process on external metal tags doesn’t make a lot of sense when other tag processes are more effective.

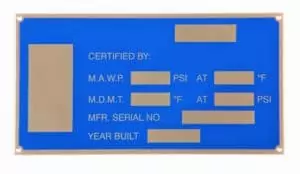

Sometimes they are used to add information to an already completed metal nameplate. Such as filling in blank spaces with specific info.

This allows for ordering of bulk nameplates which follow the same template. They can be marked on-site as they are needed.

Industries

Using dot style marking makes a lot of sense for certain industries. One major benefit to the process is that it is does not need to use significant force to mark the material.

For industries like oil & gas or aerospace, many parts and equipment are sensitive to damage. This can lead to potential issues when attempting to directly mark machinery. Issues in these environments may become safety hazards.

For example, using hand stamps on a thin material may cause the indentations to break through. Plus, the jolt of stamping may warp the material or negatively affect other parts.

Stylus-based marking uses a less intense impact than some other processes.

For marking directly on equipment, dot pinning is an effective solution.

A Simpler Solution

Directly embedding information on your equipment might seem like a convenient idea. However, marking machinery directly means purchasing your own dot pinning machine and spending the hours to complete the task in-house.

This is a stark contrast to the simple route of purchasing custom identification tags. You order nameplates exactly as you need them, and simply have to adhere or attach the complete tags to your machines as need be. No additional work required, and no hours of manually marking tools and equipment.

Getting tags from a third party also eliminates the potential for human error when directly marking each tool. Imagine if your six-figure piece of equipment gets the wrong data matrix code permanently stamped in it.

For the majority of organizations this is why ordering identification plates from a third party is the best (and most cost-effective) solution.

Drawbacks

Slow Speed

A major drawback for dot peen marking is that it is a very sluggish process. The stylus has to individually strike the material for each and every dot in the design. For one or two machines, no problem. But if you are marking an entire inventory of tools, or a large factory full of machines, this turns into a major issue.

Metal identification tags can be produced in a fraction of the time it would take to mark that much equipment. The additional time constraint of dot marking is something to keep in mind when heading down that route.

Legibility

There are also some legibility concerns with this process. It doesn’t make clean, crisp lines. In certain cases it can be challenging to decipher the dot patterns.

There is also no option for color.

For very simple designs such as a few numbers or characters, the dotted design will probably be fairly easy to read. However, a process like embossing or MetalPhoto are significantly more legible.

For a serial number that needs read once a year, this probably isn’t a big deal. For safety info that needs accurately seen daily, this becomes a greater concern.

Data Options

There are some options for customizing your marked designs. The dots can form into any pattern you wish them to. This includes letters, numbers, or special characters.

Dot pinning is also able to create data matrix codes. Data matrix codes are used for tracking assets as well as providing additional information. However, this process cannot create working QR codes or lined barcodes. This is a potential drawback if your organization relies on them for a tracking system.

If you have a simple logo design or image such as a star or heart, it can handle those as well. Anything beyond that will get very difficult to create without looking like a mess of dots.

Wrap-Up

In short, metal dot peen marking is a useful solution in certain situations. The ability to embed directly onto equipment is a unique way to add information. Plus, the option to add data matrix codes alongside text is a great benefit as well.

Alongside the positives, there are a few drawbacks. Customization is limited to only text and data codes. There is no option for QR codes, barcodes, or images.

Legibility issues are something to keep in mind as well, as dotted designs may be more difficult to read than straight lines.

In comparison to other processes, dot pin designs take much longer to embed. If you are only looking to add information onto a few machines, it might be perfect. Any larger quantities and you start running into major hassles.

In that case, you might be better suited for a different identification process.