Photo anodizing is the process of sealing an image into anodized aluminum, creating a highly durable metal tag. Although photo anodizing has many applications, it’s especially common in the pump industry, which develops products intended for use under extremely harsh conditions. Keep reading to learn more about photo anodizing and what benefits it offers for firms in the pump industry.

Applications of Metal Anodization

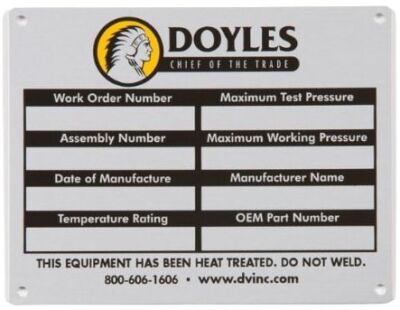

Metal anodization produces a high-quality image, so the process has many applications in the pump industry. One of the most common is the production of irrigation valve tags. Irrigation systems are complex, so it’s important for each component to be labeled with detailed identification information. Identification tags make it easier for operators to distinguish between pumps, valves, and other system components, reducing the amount of time it takes to identify a part and determine what type of maintenance or repair it requires. Anodized identification tags can also be used on pumps, flow meters and other items used in the pump industry.

Photo Anodizing vs. Embossing and Etching

Photo anodizing isn’t the only process used to create custom metal tags, but it produces some of the best results at the most affordable price point. Embossing uses a die set to produce raised characters on a piece of metal, eliminating the need to worry about fading ink. Although the durability of an embossed tag is comparable to the durability of a photo anodized tag, embossing can be more expensive. This is because each new design requires a new die set.

Etching involves making impressions on a piece of metal. This can be accomplished with the laser etching method or the chemical etching method. During laser etching, a high-powered laser etches a design directly into a piece of metal. Chemical etching involves removing portions of the metal, leaving a finished design behind. Etched products are durable, but they aren’t quite as durable as products made with the anodization method.

Customization of Anodized Products

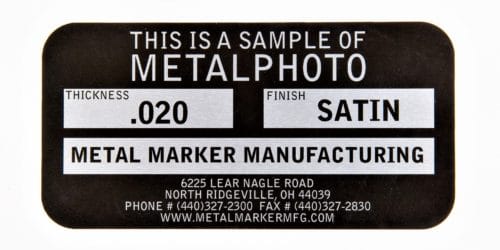

Many of our products are made with metalphoto, a specialized type of aluminum that’s more durable than other metals. The use of metalphoto makes it possible to create almost any type of metal tag you can imagine, from simple identification tags to tags with colored backgrounds and corporate logos. Photo anodizing allows us to customize the shape, size, thickness, and finish of each tag, giving you a completely customized product that meets your identification needs and matches your branding guidelines.

Benefits of Photo Anodizing for Firms in the Pump Industry

Tags created with the metal anodization method have many benefits for companies operating in the pump industry. These are just a few of the most significant.

Durability

As noted previously, photo anodizing produces a highly durable product that stands up to even the harshest conditions. If your company uses valves and pumps outdoors, anodized tags are durable enough to withstand sun exposure, heavy rains, snow, and extreme temperatures. Even if you plan to use them indoors, you need identification tags that won’t wear away or disintegrate if they’re placed near freezers, water heaters, boilers and other equipment that has an effect on the temperature or humidity of the environment.

Increased Safety

Although anodized products are available in several finishes, none of those finishes have toxic ingredients, making them safe for indoor and outdoor use. Photo anodized products contribute almost nothing to air and water pollution, so you can take comfort in knowing you’re fulfilling your identification needs without compromising your commitment to environmental safety. You can even recycle anodized aluminum, making photo anodized products a good choice for firms that are committed to sustainability.

Visual Appeal

Because photo anodized aluminum is so durable, we can offer several customization options without compromising the structural integrity of each tag. Whether you want a glossy finish or a colored background, photo anodized tags are visually appealing and make your pump company appear extremely professional. Metal Marker Manufacturing can even make metal tags to match your current branding scheme, making it easier to promote your brand in the marketplace.

Cost Savings

Anodized aluminum may cost a little more upfront than other types of metal, but its durability results in significant cost savings over time. Flimsier tags may need to be replaced every one or two years, forcing you to spend money every time ink fades or a tag fails to hold up under harsh conditions. Tags made with anodized metal may last for a decade or more, eliminating the need to purchase replacements for many years to come.

Using anodized tags can also help your firm limit expenses associated with poor inventory management or the misidentification of company property. Anodized tags are useful for tracking equipment and parts, ensuring you always know what you have on hand. You won’t need to worry about replacing lost equipment or spending money on parts you already have when everything is clearly identified by durable metal tags.

Choosing Anodized Products

Before you start creating your first design, here are a few things to consider when choosing metal tags made with the anodizing process.

- Does the metal tag need to have full conductivity?

- Do you need several copies of the same tag, or do you need multiple custom tags?

- Is it important to achieve a true color match with each tag?

- How thick does the tag need to be?

- How will the tag be used? Are the conditions especially harsh?

Metal Marker Manufacturing has extensive experience producing high-quality custom identification products made from anodized metal. To learn more about how we help companies in the pump industry keep track of their assets, call us at (800) 428-0095, or visit our website to discover your custom metal solution.