Customized Metal Asset Labels for Inventory Management

At Metal Marker, we produce fully customized abrasion-proof metal asset tags for a wide range of industries and applications. Our metal identification tags are used to label and track any number of organizational assets and equipment. This includes machinery, tools, equipment, and more.

We manufacture a wide range of custom metal labels such as aluminum asset labels, embossed nameplates, metal barcode tags, metal equipment tags, and UID tags.

From stainless steel tags with serial numbers to aluminum nameplates with a data matrix, or even labels with QR codes; we can pretty much do it all. A few examples of our label material options include:

- Stainless Steel Tags. Stainless steel asset tags are your choice when your ultimate goal is high quality and durability. They’re heavier and more expensive than aluminum tags, but stronger and more resistant to corrosion. They won’t break down from wear and tear or extreme heat. Stainless steel is the ideal choice for many applications for this reason.

- Aluminum Tags. is the single most popular type of metal asset tag. This popularity of aluminum tags is due to the fact that aluminum is durable and strong, but also lightweight and cost-efficient. In comparison, other types of metal can’t compete.

- Brass Tags. Brass is valued for its appearance or its corrosion-resistance qualities. Brass asset tags withstands harsh environmental conditions. Brass asset tags are particularly suitable for outdoor use, as they can endure exposure to the elements over an extended period.

What Are Asset Tags?

Metal asset labels are used to identify, track, and manage items in a variety of industries and applications. Most commonly, these tags are used to track inventory within a business. This could be things like equipment, materials, or a finished product.

By utilizing custom asset tags, businesses can simplify their internal record-keeping to be more organized internally while also continuing to offer support for their products after they are sold. Many of our metal tags are made from anodized aluminum, but materials can vary depending on the application.

What our metal labels offer that others don’t is long-lasting durability and legibility. If a piece of machinery is outdoors for multiple years, other asset management solutions may deteriorate and be hard to read. Our labels have proven to last over 20 years and still be just as strong and readable as the day they were made.

What Industries Use Our Asset Tags?

Our tags are versatile, durable, and able to withstand the high temperatures of industrial settings. That being said, these tags have found use in many different settings with many different niche applications. If you need a customized metal asset tags solution, we’re confident we can make it for you.

Here are some of the industries that need metal asset tags:

- Aerospace – Asset tags are essential tools in the aerospace industry for improving efficiency, ensuring safety, complying with regulations, and maintaining the reliability of critical components and equipment throughout their lifecycle.

- Automotive – Asset tags help the automotive industry track and manage a wide range of equipment, components, tools, and machinery. Each asset is assigned a unique identifier, often in the form of a barcode or RFID tag, allowing for efficient tracking throughout its lifecycle.

- Defense – Defense companies often deal with a vast inventory of components, tools, and equipment. Asset tags facilitate efficient inventory management, helping them keep track of stock levels, reduce errors in inventory counts, and improve overall supply chain management.

- Energy – Metal asset tags play a vital role in the energy industry by facilitating efficient asset tracking, promoting safety and compliance, optimizing resource utilization, and contributing to the overall reliability and integrity of energy-related assets.

- Manufacturing – Manufacturing companies often deal with large inventories of spare parts, tools, and equipment. Asset tags assist in efficient inventory management, reducing the risk of errors in stock counts, improving supply chain management, and optimizing resource utilization.

- Government – The government is subject to stringent regulations and standards. Asset tags help organizations comply with these regulations by providing a documented history of assets, including maintenance records, inspections, and other relevant information required for regulatory reporting.

- Oil and Gas – Safety is a top priority in the oil and gas industry. Asset tags contribute to safety by providing a means to identify and trace critical components, ensuring that they meet safety standards and regulatory requirements. This is especially important in environments where compliance is closely monitored.

- Supply Chain Logistics – Assets that have long lifecycles require careful management. Asset tags help organizations understand the usage history, maintenance needs, and replacement schedules of assets, contributing to effective supply chain and lifecycle management — serving to reduce overall operational costs.

- Telecommunications – Metal asset tags play a crucial role in the telecommunications industry by facilitating efficient asset tracking, improving security, ensuring regulatory compliance, optimizing resource utilization, and contributing to the overall reliability and performance of telecommunications networks.

- Warehousing – Companies often maintain large inventories of spare parts and equipment in a warehouse. Asset tags provide a systematic and efficient way to track and manage a wide range of assets in a warehouse.

What Do I Need for Asset Tracking?

I want to start asset tracking, but what do I need? The very basic requirements for a bar code tracking system includes: computer software, scanning tools, and barcode tags.

Asset Tracking Software

In order to set up the asset management system, you’ll need computer software that will manage everything, read/write information that is scanned, and create a record. There are many options for software for the industry and size of your organization.

Along with the software, you’ll need to get at least one scanning tool to log and scan tags. However, if you have a large operation with many departments you may need multiple scanners.

Barcode Tags

Last but not least, you need the barcode tags themselves. These can be made with either metal or plastic, depending on the environment and conditions they need to be used in. The most popular choices for barcodes are QR codes or UPC style barcodes. These make data collection a breeze.

Outside of traditional barcode tags, there are other higher-tech tracking options. For example: NFC, RFID tags, Wi-Fi, Bluetooth, and even GPS tracking. Mobile computers can even provide data on-the-go. These tracking technology options might be necessary for some organizations who need real time information. However, they come at a much steeper cost, making them unnecessary for most. As blockchain technology advances, barcode tags will become even more crucial.

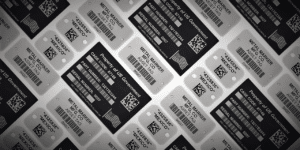

Metal Barcode Tags

One of the most popular methods of asset tracking is utilizing a barcode label scanning system. We produce metal barcode labels that are compatible with any type of inventory control system your organization uses.

QR code tags have the ability to store large amounts of information. You can easily scan them with your smartphone or barcode readers. They can be coupled with asset tracking software for the biggest impact. Data Matrix Codes are frequently used for tracking Military Unique Identification Tags (UID).

Numbered Tags

Implementing a barcode scanning system isn’t the right fit for every organization. Whether you prefer to keep things simple with basic metal signage, or just don’t want to invest in barcode technology, we offer a more straightforward solution.

From machinery to utility poles, our serialized number asset tags are used to track and manage inventory across the country. These tags are relied upon for inspections, tracking, servicing, and more. Numbering your inventory is still considered effective asset tracking.

Inventory Management

Many organizations need to keep track of inventory levels. This may include simply monitoring stock levels, or even automatic reordering systems when quantities get low. By using a scanning system, the inventory control process becomes considerably easier. This can be beneficial for insurance reasons, inventory valuation, and more. This can be beneficial for insurance reasons, inventory valuation, and more.

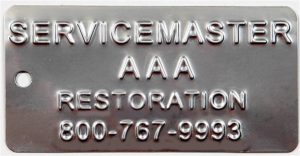

Theft Prevention

In addition to asset management, throwing a metal tag on your expensive tools and equipment can help to prevent tamper attempts. A simple “property of…” marker can deter someone from sneaking off with that new company drill. Labeling your equipment is a fast and simple way to help prevent unwanted use or theft.

Custom labels can also provide contact information should a tool or component go missing or end up in the wrong hands. For example, a construction site with many contractors may result in equipment mix-ups. By marking your gear with security labels, the likelihood of loss is much lower.

Photo Anodization for Foil Asset Tags

One of our most popular processes for asset tags is photo anodization. This process seals your design beneath an anodic layer of anodized aluminum, providing outstanding durability (20+ years outdoors).

For aluminum labels, it is hard to beat photo anodization. The durable tag markings it produces are high quality, easy to scan, and won’t easily wear off if exposed to the elements or harsh environment. This process also allows for more than just barcodes, as it can include custom logos, designs, and more.

Anodized aluminum labels can be attached directly to physical assets using permanent adhesive.

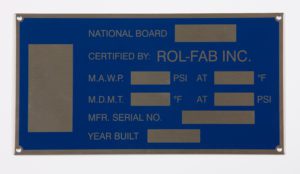

Embossing

For organizations looking to use serialized number tags for inventory management or equipment marking, we provide custom metal embossing. This process creates highly durable raised characters in the material. These tags are sometimes preferred due to their simplicity, and extreme durability.

The raised metal can hold up to even the harshest industrial conditions. The embossing process allows for top-level durability, with upwards of 20+ years of usage in most environments for marking physical assets. Organizations turn to the embossing process when they need the utmost durability while maintaining easy-to-read id tags. Destructible ID tags are not particularly useful in hard-hitting industries.

Digital and Screen Printing

We also offer printing methods, whether it be on metal asset tags or custom decals. One major advantage to printing is we can include a full-color logo or additional branding, alongside a barcode label or data matrix. Vinyl or polyester tags are less durable, but provide a good alternative in some situations such as GHS asset labeling. These ID labels attach with adhesive backing, just like applying stickers.

Related Blogs

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.