Do you need to mark your equipment? Metal Marker manufactures high-quality metal equipment tags designed to mark your equipment. Our equipment ID tags are custom-made with a variety of processes to fit your exact specifications and pricing needs. We offer the best quality, price, and service in the industry.

You can trust that our products will stand up against harsh weather conditions while maintaining legibility for years on end. Our durable equipment tags are designed to be exposed to moisture and extreme temperatures of outdoor applications.

Interested in receiving a quote on your project? Contact one of our customer service representatives and they can fit you with the perfect solution for a reasonable price.

Call 1-800-428-0095 or fill out our request for a quote form today.

Overview

Equipment tags are used to mark important information about the equipment they’re attached to. This includes machinery numbers, asset numbers, locations and more. These items can be easily lost or stolen without proper marking so it is extremely important that you have them properly labeled.

Additionally, compliance is another facet our equipment tags are used. Machinery needs to be up to code to ensure the safety of their operators in addition to providing quick information at a glance for inspectors.

In various industries, equipment tags streamline asset management, promote workplace safety, as well as provide essential information for maintenance and inspections.

When your operation depends on clear and reliable equipment identification, it’s crucial to choose equipment tags that can withstand harsh environments and last for years with their information remaining clear and legible.

Metal Marker has been crafting durable, custom equipment tags since 1923. Made in the USA, our tags are designed for any industry, from construction to manufacturing. Call (800) 428-0095 or fill out our form for a no-obligation quote.

Applications

Our custom metal equipment tags are suitable for use in various environments, from construction sites to factories and warehouses. Here are some common applications:

Equipment Identification

Equipment tags are an excellent choice when you need a long-lasting labeling solution for machinery, heavy equipment, and tools. They can be customized to show calibration data, operating instructions, model and serial numbers, ownership details, and other important information.

Safety and Compliance

Tags with safety information — such as weight limits, load tolerances, and usage guidelines — enhance workplace safety and help reduce the risk of accidents. In industries like construction and manufacturing, proper tagging also helps businesses comply with safety standards and regulatory requirements.

Repair and Maintenance Tracking

Tags marked with “Do Not Operate” or other repair-related messages clearly identify defective equipment to improve safety. Barcodes or QR codes on tags allow for streamlined tracking of maintenance schedules and repair histories, ensuring that equipment stays in excellent running condition.

Asset Tracking and Management

Serialized tags, barcodes, and other tracking systems help you manage assets and inventory efficiently. Whether you need to label equipment with serial numbers or integrate QR codes, you can rely on us for customized tags that meet your business’s needs.

Materials

Metal Marker’s custom metal equipment tags are crafted from high-quality materials designed for reliability in demanding environments:

- Aluminum: Lightweight and corrosion-resistant

- Stainless Steel: Excellent resistance to chemicals and extreme temperatures

- Cold Rolled Steel: Durable and cost-effective

- Brass: Suitable for both functional and decorative uses

Using durable metal materials for your equipment tags, it ensures that your labeling will stay sturdy and legible for years to come.

Processes

Metal Marker offers a range of customization options to meet your exact requirements. Each of these has its own set of benefits are drawbacks.

Embossing & Stamping

Our embossing and stamping processes are tried and true methods for marking equipment tags. This is a simple but effective solution that is used to mark equipment, tools, and other machinery.

These metal tags are typically made with mounting holes and attached with screws or wire. In the case of equipment valve tags, a wire can be used to hang them from the valve.

Unlike other processes, embossing and stamping create direct impressions in the metal. Stamping indents a design while embossing raises the characters upwards.

Since there is no ink to be removed, these designs are incredibly durable and long-lasting. You will see years of use out of these tags before they need to be replaced.

Marking blank equipment tags in-house with an embossing machine or hand stamps is also an option.

Embossed tags feature raised characters for high visibility and durability.

A stamped equipment tag has an indented design that is easy to read and highly resistant to wear.

Photo Anodization

One of our most popular processes is photo anodization. With this process, we have the capability to add any customized design you need. This can be an image, a barcode, a logo, or any other data you require.

Photo anodized equipment tags can be attached in a variety of ways. Many customers choose to add an adhesive backing to attach the labels directly to the machine while others opt for mounting holes to be drilled into the surface for the use of bolts or screws.

Worried about the durability of your design? With our photo anodization, you no longer have to. These metal equipment tags are rated for 20+ years outdoors, in all weather conditions. They are more than able to withstand the wear and tear of your industrial application.

You can embed custom designs such as logos, barcodes, or QR codes into anodized aluminum with photo anodization. Also exceptional when you have variable information for individual tags. These tags are lightweight, corrosion-resistant, and rated for 20+ years of outdoor use.

Digital and Screen Printing

If you must mark your equipment with a colored design, screen printing is a solid alternative. A custom design is printed onto the metal labels, creating a clear and easy-to-read image.

The biggest drawback is the downgrade in durability. Since these plates feature topical ink, that design is subject to wear and tear, as well as fading in sunlight.

While not as durable as other processes due to topical ink, digital and screen-printed designs do stand out from their metal surroundings, making them effective at communicating information.

Engraving

Engraved tags are ideal for applications requiring detailed and hard-wearing labeling.

Etching

Etched tags can be colored for enhanced visibility. While less durable than other types, these tags are a great choice for indoor or temporary applications.

Examples

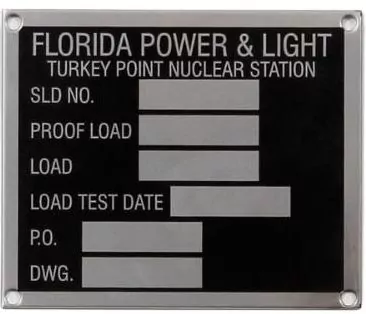

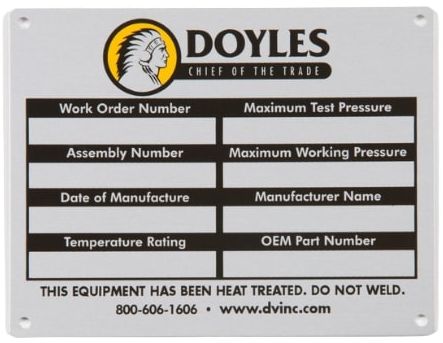

Here are a few examples of equipment tags we’ve made for customers:

Equipment ID Tags

Your equipment needs to be marked with pertinent information.

Equipment inspection tags and identification tags help ensure proper usage practices and calibration are being followed. In addition, this can prevent costly errors before they occur.

Identification tags also help when it’s time for inspections. Even if your equipment is not officially mandated to be marked by OSHA, equipment tags and equipment inspection tags can help aid inspectors or servicers to quickly and accurately complete their tasks by providing maintenance information for easy visibility.

Equipment Safety Standard Tags

Safety is crucial, especially for industrial organizations. Conditions can be unsafe in areas such as construction sites or factories if the proper safety information is not communicated or adhered to.

Equipment safety signs can include weight/load tolerances, a service number, building graphics, proper usage techniques to prevent accidents, and other calibration specifics.

Repair Tags

Identification is also important when machinery is under maintenance. Defective equipment or machines under work orders can be dangerous to operate. Marking this equipment with a repair tag reduces costly errors.

These forms of equipment tags provide easy visibility to messages such as “do not operate” or “do not enter.” This signage coupled with lockout tags is essential to a safe environment. Our equipment tags are perfect for keeping your warehouse, factory, or job site safe with clear and accurate information.

Asset Identification Equipment Tags

Tracking and managing your equipment and other assets is crucial for your organization to be efficient and effective. By using metal equipment tags, you add a layer of traceability to your assets.

This can be as simple as serial numbers or as complex as a photo anodized tag with barcode labels integrated into a digital asset management tracking system. The best solution is the one that fits with your organization. We are happy to work with you to find the perfect equipment tags.

Wrap-Up

Order Durable Equipment Tags for Your Business

Equip your business with tags built to last. Metal Marker Manufacturing offers high-quality, custom equipment tags that deliver the durability and reliability your business needs.

Call us at (800) 428-0095 to discuss your project, or send us a message via our online form.

Testimonials

You’re not gonna find a better company when it comes to knowledge in the label/marker field. Metal marker is extremely responsive and truly cares about their customers and goes out of their way to get their customers exactly what they’re looking for, Every Time!

Metal Marker was fantastic at explaining options, costs and work with our design needs, the items arrived sooner than expected and each plate was protected with a film, the tape is very strong and we hope it last for a long time as the plate goes on the rim of the main door, is our branding.

The Metal Marker team is amazingly patient and got us exactly what we were needing.

Tags Look Great, exactly what we were looking for

Easy to work with Metal Marker. They are organized and delivered product with high quality.

Great products every time! Great customer service!

Everything is great ! good service, and customer service.

I’m very impressed with everything that you guys do and I’ve been very pleased with the projects that we’ve worked on. Count on me to be in touch with you on any upcoming projects that are moving forward.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.