Utility and telephone poles line our streets and highways, and most of the time don’t get much more than a passing glance (unless there’s an issue). Yet they are very much the backbone of our electric power and communication systems.

It takes a lot of work to keep those systems running smoothly. Inspecting and servicing utility poles is not the easiest job in the world. It’s also very time-consuming. High durability telephone pole tags make the task manageable.

To learn more about our products, fill out the Free Quote form. You may also call (800) 428-0095 to discuss your requirements.

Overview

Utility pole tags are essential for managing infrastructure, providing key identification that streamlines operations such as inspections, maintenance and asset tracking.

Metal Marker designs custom utility pole tags suitable for various industries and environments.

Benefits

Why Would Utility Poles Use a QR Code?

Code scanning is an incredibly useful tool for an enormous number of industries. From logistics firms to companies needing a better way to track and manage their assets, the uses are endless.

Tracking software provides a wealth of information about a given asset.

For telephone poles this may include:

- GPS Location

- Condition of the pole

- When it was last serviced or inspected

This information makes inspection incredibly easy. Instead of writing down a bunch of numbers in a notebook, a scanning app can both read and write the information necessary. This makes for quick and easy identification.

Applications

Inspection

Telephone poles always feature some sort of pole identification system and pole ownership marking. Whether it’s plastic signs, metal nameplates, or carving in the wood itself. Sometimes it is a combination of all three.

Every pole must be inspected individually which is a very time-consuming process. As a result, having clear and accurate information on each pole is an absolute must. This not only saves the inspector valuable time but also ensures the reliability of data and prevents human errors resulting from manual data collection.

Durability

When it comes to pole identification tags, exceptional durability is the name of the game.

When it comes to pole identification tags, exceptional durability is the name of the game.

In short, utility poles do not sit inside air-conditioned offices (and neither do their inspectors). They are out in the elements 7 days a week. It doesn’t matter if it rains, snows, or freezes; pole tags need to endure prolonged exposure to harsh environments.

Not only do the pole markers have to survive in tough environments, they also need to last for a long duration. Replacing thousands of tags on a yearly basis would be incredibly expensive and time-consuming. Selecting nameplates that last for upwards of 20+ years outdoors makes much more economic sense.

Materials

The choice of material depends on the specific application. Some of the most common options include:

- Aluminum

- Photo Anodized Aluminum (MetalPhoto)

- Stainless Steel

Every company, environment and situation is unique. For example, some telephone companies use color-coding systems, making anodized aluminum an ideal choice. Its durability and lightweight nature make it perfect for outdoor use, while its colorization option seamlessly integrates into color-coded systems.

Stainless steel embossed tags offer exceptional durability, making them the perfect choice for a permanent outdoor solution. Ideal for use in areas prone to extreme conditions, stainless steel tags are highly resilient, resisting corrosion and damage over extended periods.

Photo-anodized aluminum, on the other hand, offers exceptional versatility. This process lets you customize utility pole tags with barcodes, logos or safety messages.

Processes

These nameplates require processes that hold up to all weather conditions. The two most popular processes for this application are embossing and MetalPhoto.

Embossing

This is probably the process you picture when thinking about utility pole plates. The characters are molded into the metal using a custom die set, giving utility pole tags a three-dimensional look and feel.

This process is perfect for serialized numbers on pole tags — commonly used for this purpose. Serialized nameplates simplify numbering large quantities of poles, and companies often include the last inspection date and their name for easy reference.

Additionally, embossed utility pole inspection tags are easily readable even at a distance, making them great for quick inspections. Anodized aluminum can also feature colors for added visibility or color coding.

Embossing ensures long-term legibility even in challenging environments, making it the go-to option for high-visibility applications. The best part is that they are incredibly cost-efficient without sacrificing quality or durability.

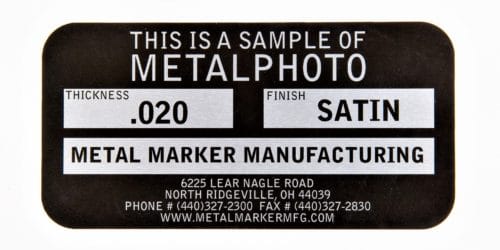

MetalPhoto

Another option is utilizing the photo anodization process. MetalPhoto directly embeds a design underneath an anodic layer of aluminum material. This creates exceptionally durable power pole tags that can last up to 20 years.

With MetalPhoto, the sky’s the limit in terms of customization. Companies typically identify pole location, number or both. They may also add a logo or a contact number, specific designs or additional text.

The anodization process allows for the addition of color. Pole tags often feature large black text on a colored metal background.

MetalPhoto is ideal for companies requiring tags with intricate details, such as maps and diagrams, to improve utility management. Its ability to incorporate advanced features like scannable QR codes and barcodes adds functionality, making asset tracking and inspections easier.

Wrap-Up

Simplify Utility Pole Tracking and Management With Top-Notch Metal Tags

Utility pole tags and labels provide important safety information for a range of applications. From aiding in periodic inspections to keeping accurate identification in labeling hazardous equipment, there is no limit to their utility.

Maintaining utility and telephone poles is incredibly important and that includes replacing defective pole tags. Proper identification makes inspections easier, more effective, and more efficient.

Getting the most use out of the poles as possible while maintaining safety standards is crucial. By correctly utilizing embossed and photo-anodized tags, pole companies can make the most out of their assets.

Need Pole Tags?

Metal Marker Manufacturing Company is a trusted provider of high-quality, customizable metal tags for utility poles. With a wide range of materials and advanced manufacturing processes, we offer tags tailored to meet the specific demands of your operating environment.

Metal Marker’s knowledgeable customer service representatives are ready to assist you in finding the perfect solution.

To learn more or get a free quote, please send us a message or call (800) 428-0095.

Testimonials

You’re not gonna find a better company when it comes to knowledge in the label/marker field. Metal marker is extremely responsive and truly cares about their customers and goes out of their way to get their customers exactly what they’re looking for, Every Time!

Metal Marker was fantastic at explaining options, costs and work with our design needs, the items arrived sooner than expected and each plate was protected with a film, the tape is very strong and we hope it last for a long time as the plate goes on the rim of the main door, is our branding.

The Metal Marker team is amazingly patient and got us exactly what we were needing.

Tags Look Great, exactly what we were looking for

Easy to work with Metal Marker. They are organized and delivered product with high quality.

Great products every time! Great customer service!

Everything is great ! good service, and customer service.

I’m very impressed with everything that you guys do and I’ve been very pleased with the projects that we’ve worked on. Count on me to be in touch with you on any upcoming projects that are moving forward.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.