Aluminum tags are a perfect color metal choice for industries like manufacturing, telecommunication, and other applications. The aluminum is treated with an electrochemical process. This process improves the resistance to corrosion by adding an anodized layer to the surface of the aluminum.

Any color can be added during the anodizing process for a stand-out appearance or color-coding purposes. The color is literally embedded into the aluminum!

Metal Marker is the prime manufacturer of wholesale aluminum tags and other metal identification tags — made right here in the USA. We offer fully custom designs of any shape, size, or color. If you’re interested in learning more, please visit our website or call us: (800) 428-0095.

Overview

Custom aluminum tags offer a versatile solution for identification, branding, and asset management. Known for their lightweight yet corrosion-resistant properties, these tags are ideal for both indoor, outdoor and harsh environments applications.

With advanced marking techniques, anodized aluminum tags provide clear, long-lasting identification tailored to the needs of various industries.

Benefits

Why Should Your Business Use Aluminum Tags?

Color Choices

Need your aluminum tags to stand out? We offer a wide range of colors for any industry. Coloring the anodized aluminum tags allows for color-coding, branding, or high-contrast colors for increased visibility. Unlike stainless steel or brass tags, the bright silver color of aluminum tags is great for low-visibility environments or just to make the message pop.

While adding a surface color is possible on various tags, only anodized aluminum tags have the dye embedded into the material. This is then sealed with a thick anodized layer for added durability.

This coating makes anodized aluminum tags perfect for withstanding temperatures from freezing cold to boiling hot. They will withstand harsh chemicals, wear and tear, and anything else you throw at them.

Durable and Scratch Resistant

Whether your aluminum tags are in a warehouse full of chemicals or a rainy construction site, durability is always a concern. Aluminum labels are made to withstand temperatures of tough environments in nearly any industry.

The anodized coating introduces anti-corrosive properties to the aluminum, allowing it to withstand water and chemical exposure, making it perfect for outdoor applications. The aluminum tags are strong enough to withstand harsh weather and high temperatures.

Unmatched Readability

These aluminum tags’ bright silver color is extremely reflective and easy to read. Pair this with a strong processing choice, and your tags will become a permanent part of your equipment.

Industries

Industries That Use Aluminum Tags

A wide range of industries depend on anodized aluminum tags for asset labeling, compliance tracking, and equipment identification.

Manufacturing facilities use them for machinery labels, while the aerospace and automotive sectors require durable identification for critical components.

Healthcare, telecommunications, and military operations also benefit from aluminum tags due to their resilience in demanding environments.

Custom

Customization Options for Anodized Aluminum Tags

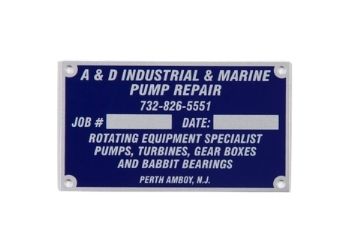

Businesses have several options for customization, which can be tailored for their business needs. Anodized aluminum tags can be outfitted with asset tracking and branding elements to make each item unique. They can be fully personalized with various design elements, including:

- Logos and Branding: Enhance brand visibility with high-resolution, fade-resistant graphics.

- Serial Numbers and Unique Identifiers: Ensure traceability and security with precision numbering.

- Barcodes and QR Codes: Optimize scanning efficiency for inventory and data management.

- Durable Markings: You can add photo anodization for detailed imaging or stamping and embossing for long-lasting, wear-resistant text and designs.

These customization techniques can be combined with high-contrast markings that can help with identification and make each tag unique for better tracking.

Why Choose Metal Marker for Custom Aluminum Tags?

Metal Marker provides high-quality, custom aluminum tags with superior durability and precision. Our advanced marking processes ensure long-lasting, legible identification solutions for any industry. We provide anodized finishes, and serialized tracking, delivering customized solutions to meet your needs.

Applications

Common Applications of Custom Aluminum Tags

Aluminum tags serve many applications, from industrial labeling to personal identification. Equipment manufacturers use them for serial plates and operating instructions, while utility companies label pipelines and electrical components. In aerospace and defense, custom aluminum tags provide regulatory compliance, ensuring easy traceability in high-stakes environments.

Think Aluminum Tags Are Right For You?

Anodized aluminum tags are suitable for many uses, including marking poles, tracking inventory, and identifying machines. These tags can withstand many environments and are suitable for various applications. Once you know your company wants to use aluminum tags, you must find the best ones for the task. Some companies may need multiple types of aluminum tags.

Anodized aluminum tags are suitable for many uses, including marking poles, tracking inventory, and identifying machines. These tags can withstand many environments and are suitable for various applications. Once you know your company wants to use aluminum tags, you must find the best ones for the task. Some companies may need multiple types of aluminum tags.

When you work with Metal Marker Manufacturing Company, you can discuss your metal tag needs with us, and we’ll let you know what we have to meet those requirements.

Customers sometimes ask for a specific tag when it isn’t a good fit for what they plan to use it for. In those cases, we can explain why you should choose a different tag type.

Aluminum tags have many uses. The possibilities depend on your company’s industry and many other factors. At Metal Marker Manufacturing Company, we understand that customizing these tags is important.

Processes

Processing Options For Aluminum Tags

Metal Marker is ready to assist you with any custom project or design requirements that you may have. Whether it’s an intricate logo or a simple image, we can help bring your ideas to life through these different processing options for blank aluminum tags.

Embossing

Embossing embeds the design upwards into the blank tags leaving raised characters when it is complete. These raised impressions are not only durable but also very easy to read.

Need your aluminum tags in a series of numbers or different info on each tag? Embossed aluminum tags are perfect for serialization as well as variable information.

Photo Anodizing

Photo anodized aluminum tags are only available with aluminum material. This process is versatile due to its durability and customization.

MetalPhoto anodized aluminum tags are rated for 20+ years outdoors in all weather conditions and harsh environments. Unlike dye-based printing, the design can’t be scratched off or worn away.

Wrap-Up

Let Metal Marker Manufacturing Company Help You Find the Best Aluminum Tags

When you’re ready to purchase the aluminum tags your business needs, contact Metal Marker Manufacturing Company. You can use our website’s handy quote request form or call us at 1-800-428-0095. We’re ready to provide quality aluminum and metal tags that suit your company’s needs.

Testimonials

You’re not gonna find a better company when it comes to knowledge in the label/marker field. Metal marker is extremely responsive and truly cares about their customers and goes out of their way to get their customers exactly what they’re looking for, Every Time!

Metal Marker was fantastic at explaining options, costs and work with our design needs, the items arrived sooner than expected and each plate was protected with a film, the tape is very strong and we hope it last for a long time as the plate goes on the rim of the main door, is our branding.

The Metal Marker team is amazingly patient and got us exactly what we were needing.

Tags Look Great, exactly what we were looking for

Easy to work with Metal Marker. They are organized and delivered product with high quality.

Great products every time! Great customer service!

Everything is great ! good service, and customer service.

I’m very impressed with everything that you guys do and I’ve been very pleased with the projects that we’ve worked on. Count on me to be in touch with you on any upcoming projects that are moving forward.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.