When many industries need some heavy lifting done, they turn to slings. They turn an impossible lifting challenge into a manageable task. Whether it’s a wire rope or metal chain, slings are ready to take on the assignment.

What if I need to know what the weight limit is? What type of hitch should I be using?

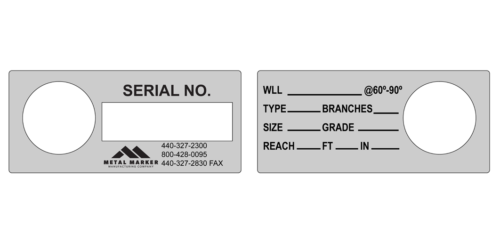

That’s where sling tags come in.

What are Sling Tags Used for?

Slings are used in a wide range of industrial settings. They are essential to construction sites across the country. Shipyards wouldn’t be able to function without them. Their ability to leverage and lift incredibly heavy loads makes them absolutely indispensable for industry use.

The ability to use slings in different configurations or hitches makes them very versatile. Some hitches keep the load balanced, while others are for distributing the weight evenly across multiple legs. For example, a basket hitch distributes the load using two legs, effectively doubling the lifting power of a one leg vertical hitch.

The material for the rope depends mostly on the application and industry. Wire rope and metal chains are two of the most popular due to their immense strength and reliability. Synthetic materials such as polyester and nylon are used as well.

Information Requirements

Sling tags have very specific information requirements. Their info is absolutely crucial in maintaining a safe job site environment.

The diameter or size of the sling will be indicated on the sling identification tag. The load the rope or chain is capable of supporting, and the type of hitch it is intended for will be shown as well. This makes sure that the operator uses the sling in the correct way. Also, the number of legs (if there are more than one) will be specified.

Sling tags often include a wealth of information. They typically have manufacturer information, such as a logo, name, and phone number. This allows the worker or company to contact the manufacturer should they have any questions or require additional information.

Plus, it’s a great way for sling manufacturers to market their product. It keeps their company name in the minds of the people using their product when it is time to order.

Barcodes

Adding a barcode is another option. This provides the ability to scan and track your slings. Barcodes can provide information such as manufacture date, how long the sling has been used, make the reordering process easier, etc. Sling manufacturers can even use them for inventory and product scanning.

Material and Process

Wire rope tags are typically aluminum or stainless steel. Both materials provide exceptional durability, even in tough environments. Aluminum also features the option for anodization if colored tags are necessary.

Most sling tag info is embedded using the stamping process. Stamping means the characters will be recessed into the metal material itself. This tried and true method allows for clear information which will not be effected by weather or wear and tear.

Durability

Some metal nameplates sit on someone’s desk and collect dust. That’s not exactly the case with sling tags.

Sling tags are exposed to the harshest work environments on a daily basis. This makes durability an incredibly important aspect.

They need to withstand all weather conditions. Shipyards and construction sites don’t shut down just because of a little rain or snow. They also need to hold up to dirt, grime, oil, and who knows what else.

Plus, they’re going to get banged up, smashed, scratched, scraped, and worn. Fortunately, that’s exactly what they’re designed to do.

OSHA/Safety

The most important thing in any work environment is safety. OSHA laws might seem like a hassle, but their purpose is to keep everyone safe.

Federal OSHA safety guidelines require slings to be marked and clearly identified using tags.

Employers now must use slings with permanently affixed identification markings that depict the maximum load capacity. …The revisions also prohibit the use of slings that do not have permanently affixed identification markings.

The information on sling tags is not there to serve as a rough estimate. Exceeding the load carrying capacity for a wire rope or chain may cause it to snap or tear. This not only puts workers in danger, but other equipment and resources may be damaged or destroyed. Under no circumstance should they be used to lift more weight than the identification tag permits.

If you are using tags, make sure to also keep them legible. Keep them clean. If they can’t be read, they aren’t helping anyone.

Don’t fail an OSHA inspection because of something as simple as keeping your wire rope identified and marked.

Wrap-Up

If you’re using slings, they need to be identified. End of story.

The tags relay crucial info to the operator. It makes their job a lot easier, as well as keeps resources and equipment from being damaged or misused.

Most importantly, ID tags keep your organization safe, and functioning efficiently. In addition, they make sure you’re up to spec on Federal OSHA safety guidelines.

The better your identification solution, the safer your work environment.