Custom Metal Tags for Your Specific Needs

Metal tags are a widely used and durable method of equipment and asset identification. Your machinery needs to be labeled with essential data for safety and operation. Our tags remain legible throughout the lifetime of the machine or asset. Additionally, we offer modern solutions for customizing metal tags such as laser engraving, QR codes, and other unique identifiers (UIDs) suitable for your business.

Metal Marker Mfg. has been in the business of making high-quality metal tags since 1923. We partner with businesses looking for long-lasting identification solutions in a wide range of industries. Regardless of quantity, application, or process, we’re confident we can produce a labeling solution perfect for your business.

Thinking of Purchasing Metal Tags?

When it comes to our custom metal tags, they’re just that – custom. We don’t implement a cookie-cutter approach like many other businesses in the industry. We tailor our metal labels and tags to the individual needs of our clients. That’s why we’ve been around for nearly a century.

Whether you need blank metal tags or you need them to be custom laser engraved, Metal Marker can do the job. We offer a variety of other processes that allow you to fully customize your tag.

Laser Engraving Metal Tags

Laser Engraved tags are highly customizable as well as economic labeling options. Our laser engraving and etching machines leave deep cuts in the blank metal tags for visibility

Stamping & Embossing

Stamping and Embossing are reliable solutions that indent or raise characters in the blank tags. Embossed tags are a popular solution when durability is a larger factor – such as pole tags where they are subject to the weather year-round.

Additionally, the embossing process also allows you to easily create duplicate or sequentially numbered tags for a lower cost.

Metal Tags Made in the USA since 1923

Metal Marker was been manufacturing all our metal tags at our location in North Ridgeville, Ohio since 1923. We know the business of industrial tags better than anyone else in the industry.

Whether you’re looking for simple labels or highly custom metal tags, Metal Marker can produce what you need.

Popular Categories of Metal Tags

What Type of Metal Materials Do We Offer?

Our custom metal tags come in a variety of different metals such as anodized aluminum, stainless steel, and brass.

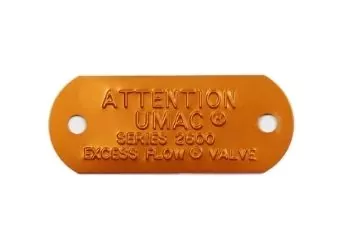

Anodized Aluminum

Anodized aluminum tags possess a unique quality in that they can be colored. We offer a wide range of colors for our aluminum tags allowing for color-coding or matching of your company’s logo.

Anodized aluminum tags are naturally reflective, which makes the metal tags stand out in low light. These can be laser engraved, embossed, or even photo anodized for a truly customized look.

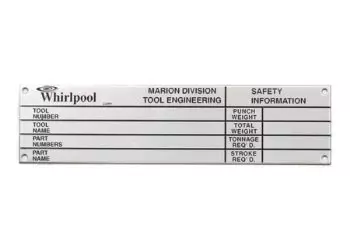

Stainless Steel

When it comes to durability, stainless steel tags are the way to go. These metal tags are often used for industrial tags due to how corrosion and scratch-resistant the material is. Further customize your tag with a variety of grades:

- 430 stainless steel: Commonly used grade fit for most industrial applications.

- 304 stainless steel: Additional corrosion-resistant properties

- 316 stainless steel: Extremely corrosion-resistant. Great for harsh conditions and extreme temperatures.

When it comes to processing and engraving, these tags have a variety of options including embossing, laser engraving, etching, and stamping.

When it comes to labeling for your company you need to be confident that they will do the job you need without fail. Our stainless steel tags often last the lifetime of the asset or equipment they’re attached to.

Brass

Brass tags have a traditional and decorative appearance and are highly resistant to corrosion. Our brass tags often come with a shiny, lacquer-coated finish which makes them a perfect decorative tag for furniture and textiles that might see a good deal of wear and tear during their lifetime.

Brass tags are often engraved or etched with your desired marking. That being said, a brass tag can also be stamped or embossed if needed.

Uses for Our Custom Metal Tags

Our labels are used in nearly every industry and application imaginable. Our tags are customizable with any image, design, or information.

Additionally, our labels are great for equipment tags by adding barcodes. The high durability of using our tags means your ID solution will hold up in harsh environments needed for heavy-duty applications. Applications with exposure to the elements such as valve tags are perfectly suited for durable metals.

Industries such as aerospace rely on our tags for their identification needs where plastic tags would not hold up. Aircraft placards are vital tag options for safety, as well as meeting required aviation standards.

Metal Marker tags and labels are used around the world in industries such as Aerospace, Construction, Defense, Marine, Chemical, Industrial, and Transportation.