Our metal nameplates are used for identification by a wide range of industries. They can be embedded with information for asset tracking, safety guidelines, or manufacturing data.

Metal material is durable enough to hold up in industrial environments. Options such as aluminum and stainless steel provide long-lasting identification.

These plates are fully customizable to allow for any design, shape, information, images, barcodes, and more.

Ready to get started? Want more info?

Our knowledgeable customer service representatives are more than happy to help find you the perfect solution.

Fill out our contact form or give us a call at: (800) 428-0095

APPLICATIONS

Safety Information

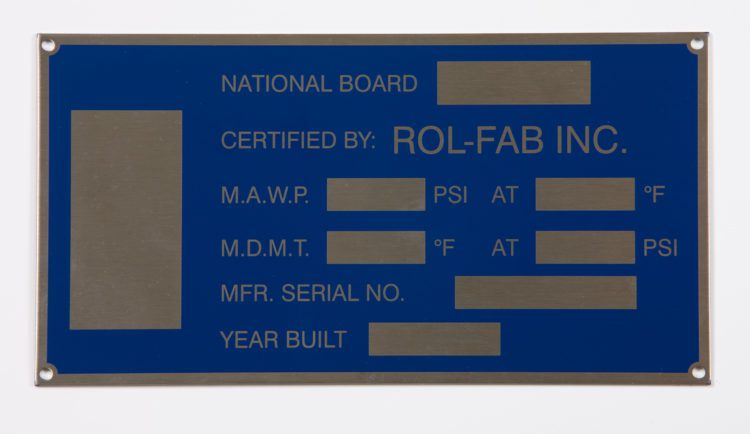

In many aspects, the most important role for equipment identification plates is to provide safety information to operators.

Our nameplates provide an easy but highly effective way to identify specific tolerances, usage guidelines, restrictions, and warnings.

While workers must be trained before operating equipment, it can be easy to forget precise information such as PSI limits, temperature restrictions, etc.

Plus, having the plate directly on the machine means there is no excuse for not having easy access to safety info.

Asset Marking

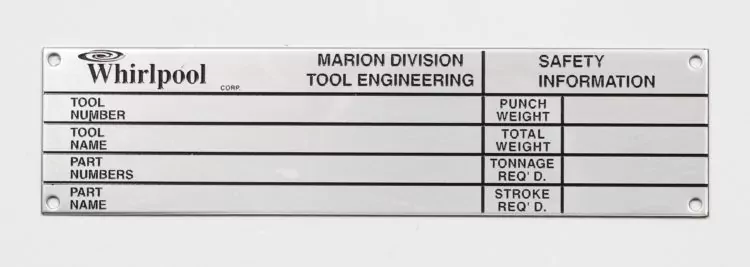

Another very common application for the nameplates we produce is asset marking and tracking.

We have the capability to produce custom nameplates with barcodes, QR codes, data matrix, and more. This gives plant managers and operators the ability to quickly obtain information about equipment with a quick scan.

By adding this layer of traceability, you can better monitor and manage your equipment and other assets.

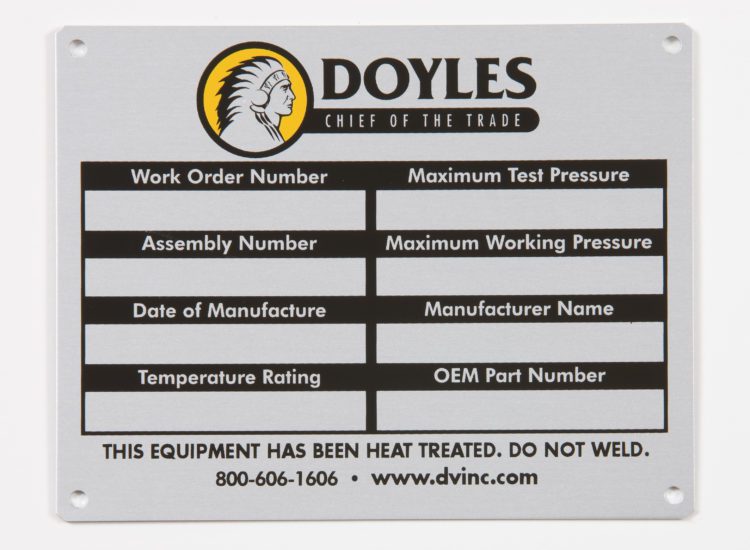

Manufacturer Information/Branding

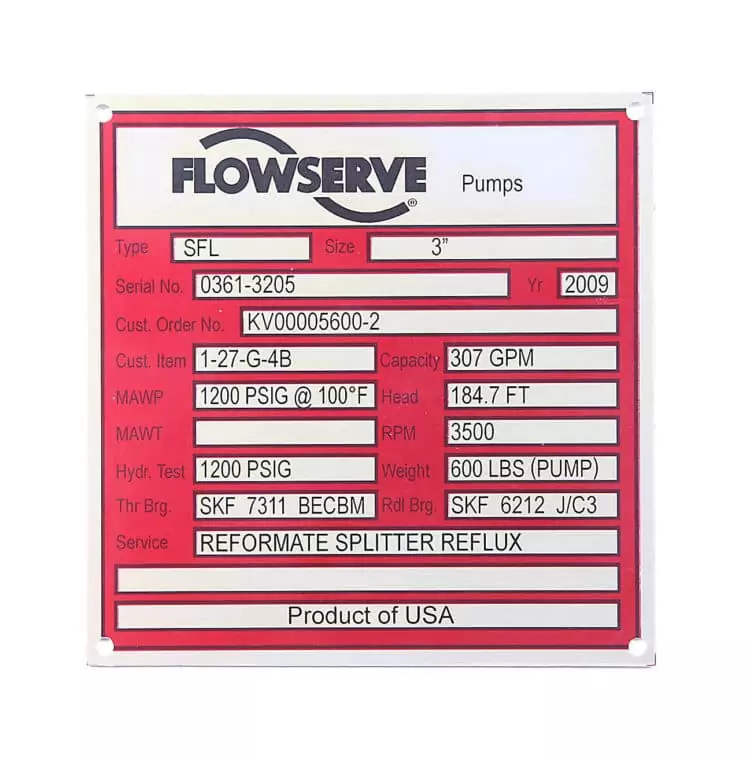

Equipment manufacturers may also add information onto their products. This can include important info for the end user as well as inspectors.

Some of the most common information added includes date of manufacture, address, or even model number.

In addition, incorporating an address or other contact information such as a support line number helps the operator know who to contact for support questions or in case of warranty issues.

INDUSTRIES

Our equipment nameplates are used every day by industries across the board.

A few examples include:

- Construction

- Energy

- Equipment Manufacturers

- Government (Federal, State and Local)

- Oil & Gas

- Telecommunications

MATERIALS

Every industry and application is unique, and each has their own specifications and requirements. This is why at Metal Marker we offer several materials to accommodate the industries we service.

Our most commonly used materials include:

- Aluminum

- Stainless Steel

- Brass

The best material choice is the one that works best for you. Know if your nameplates will be exposed to a chemical which damages aluminum? Let us know and we can direct you to a better solution.

PROCESSES

Photo Anodizing

Our photo anodization process produces an easy to read nameplate that is incredibly durable. This process embeds your design in between the layers of anodized aluminum.

The resulting nameplate is resistant to corrosion, scratching, and weather elements. Photo anodized plates are rated for 20+ years outdoors.

In addition, we can create nameplates with nearly any design. This includes barcodes and logos as well as standard text. For a stand out appearance, we can also add a solid background color to the nameplate. This is excellent for color coding as well as branding purposes.

Etching

If your equipment nameplates must include a color design, etching is a great choice. This process chemically removes metal in specified spots, resulting in a sharp looking design.

The etch and fill process allows us to add color to your text characters after they are marked. Keep in mind this fill will not last forever, as it is a topical solution.

Embossing/Stamping

Just want a basic nameplate with a serialized number on each of your equipment? What about a plain tag that just marks your company name?

The embossing and stamping processes provide a simple but effective way to mark your machinery. Embossed characters are raised upwards while stamped are indented, providing two very durable solutions.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.