Cold rolled steel tags are one of the best choices for custom metal identification. These nameplates are highly durable, and made to endure industrial conditions. Cold rolled steel’s versatility makes for an appealing identification solution.

What is Cold Rolled Steel?

Cold rolled steel (CRS) is a specialized steel. This material is sometimes referred to as cold formed steel. It gets the name due to the lack of high heat used in the production process (as opposed to hot formed steel). The material is typically very uniform.

As a result of this process, the material has very high strength and stiffness. Plus, it does not shrink at ambient temperatures. This makes cold rolled steel a great choice for many industries.

For example, CRS is often used in the construction industry for both structural and non-structural metal. This includes steel beams, columns, joints, fasteners, and more.

In some cases, a protective coating is applied to the cold rolled material as it is susceptible to corrosion.

Other Metal Properties

Cold rolled steel is often preferred due to its ease of use for welding.

This metal is also lighter weight in comparison to its heavier counterpart stainless steel. However, certain types of stainless offer different properties.

One of the outcomes of the cold rolling process is lowered ductility. If a greater level of ductility is necessary for a task, some of it can be required through the annealing process. This just depends on the application the material is being used.

Another benefit to cold rolling is the material has better non-combustibility. This makes it a perfect solution for potentially hazardous environments.

What are Cold Rolled Steel Tags Used For?

Cold rolled steel tags are used for a wide range of purposes. Here are just a few of the many applications:

- Construction Tags

- Valve Tags

- Job Tags

- Asset Tags

- And Many More

Industries

Since the material is so versatile, it is favored by a large variety of industries.

A few examples include:

- Construction

- Manufacturing

- Energy

- Oil & Gas

- Telecommunications

- Many More!

Process Options for Cold Rolled Steel Tags

CRS is a versatile material in many ways. It can be used for blank metal tags or marked to create a large number of uses. There are many marking processes to choose from.

Embossing

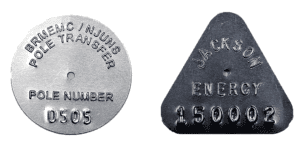

Embossed tags are known for their durability in nearly any environment. The cold rolled steel is fitted into a specialty die-set. This die set features a male and female die which create raised characters in the surface of the steel material.

Raised characters provide a high level of durability as they can’t simply be scraped or worn off. The steel characters are also very easily visible. This makes identification at a distance a breeze. Plus, if the tags are exposed to dirt, paint, or liquids, the design will remain legible.

Stamping

Another popular solution for cold rolled steel tags, stamping is also highly durable. In this process, a custom made stamp is used to directly press a design into the cold rolled metal. This creates indented characters, which are extremely resistant to wear and tear.

Stamped tags are preferred not only for their durability but their easy legibility. Stamped characters are easy to read and provide a long-lasting identification solution.

Etching

If you want to add color to your cold rolled tags, you can do so with the etching process. After the tags are laser or chemically etched, a colored fill is put into the area. This creates a bold looking tag that it very easy to read.

The one downside to this process is that this infill will not hold up to heavy use or chemical exposure. While cold rolled steel is durable, the process you select makes a big difference in the useful life of the tag.

Screen Printing

If your application calls for full color designs, screen printing is a great choice. Your design is printed directly onto the surface of the tag, creating a stand-out appearance. This can include full-color logos, text, or other designs.

Keep in mind the ink will wear over time. Since this ink is topically printed on a metal plate, once the printing wears away you will be left with a blank tag.

Wrap-Up

In short, cold rolled steel is a very versatile material. It is used for custom metal identification in numerous industries and applications. Organizations across the board rely on cold rolled tags to provide safety, identification, and traceability to their processes and equipment.