What are Metal Decals?

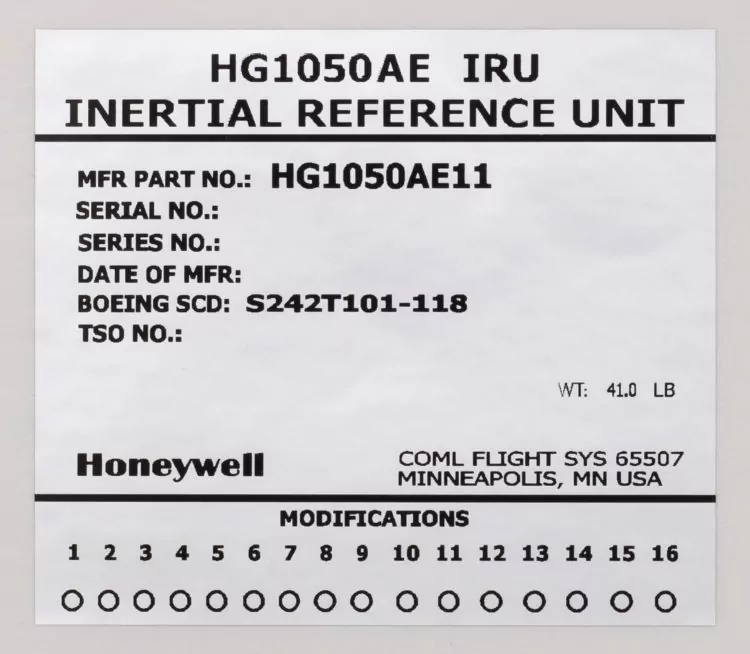

Decals and labels are an economical way to promote your company, club, or products and to identify your assets. Asset identification tags are a popular use of our serialized decals and we even have the ability to include barcode or UID markings on your decals.

Safety decals help promote safe work atmospheres. We offer safety decals, which are an inexpensive way to follow OSHA and government guidelines to meet safety regulations.

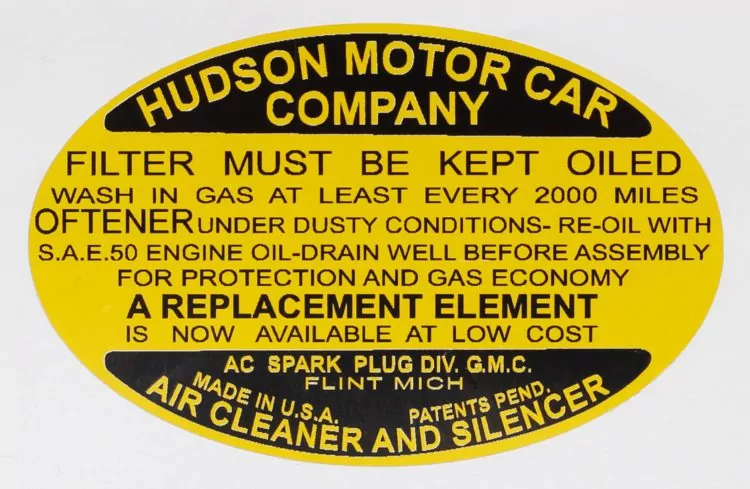

Decals can be made to your specifications or we can work with you to develop decals to meet your requirements. We have the capability to efficiently produce both small and large quantities. We have the ability to develop custom labels, custom decals, bar code decals & bar code labels, and UID decals & UID labels to the size and shape you require.

Metal Marker’s award-winning quality and delivery and knowledgeable customer service representatives make Metal Marker your source for decals and labels. Please contact one of our representatives to obtain a quote or to work with you to develop a solution to best meet your needs.

Versatility

Decals can be used for a variety of purposes and applications. They can work almost anywhere you need to place information, a logo, a car decal, badge, emblem, nameplate, or even a warning label.

One restriction with decals is they must use self-adhesive backing. It isn’t feasible to use holes in the plastic material to place them. If you absolutely must utilize holes for placement, you should lean toward metal tag options.

Keep in mind that decals and labels are not the most durable tag solution. They can hold up in certain usage situations, but they are not nearly as resilient as metal tags. This goes for stickers and adhesives as well

Another potential issue that can arise – attempting to adhere the decal to a rough or non-flat surface. This is a situational issue and needs to be addressed on a case by case basis. It depends on the surface, material, adhesive, size, and shape, etc. Your manufacturer can work with you to determine if decals will work on the surface you need.

Ease of Use

A great reason to utilize decals is their ease of use. You simply remove the decal from the roll and place them on the surface.

They can be applied in a DIY-manner by anyone in a matter of a few seconds. No expertise or tools needed. If you can place a car sticker you can place a decal.

There are no holes to mess with, no fasteners, and no rings. Peel and stick – it doesn’t get much easier than that. If you require affixing large quantities of tags on a frequent basis, you can save time by using stickers decals.

Industries

Decals and labels have many uses across various industries. For example, they can be used as safety decal emblems to follow government or OSHA guidelines. This can be an effective way to save on costs without cutting corners on important standards.

There is also the option to integrate bar codes or a UID code into the decal. This opens up the ability for use in asset tagging, as well as other applications.

By using high-quality decals instead of metal tags for your inventory management solutions you could end up saving time and money.

Industries That Use Decals

- Aerospace

- Transportation

- Energy

- Government

- Medical/Healthcare

- And More

Materials

You have many options in terms of materials for decal printing. Each material has different features and is suited for certain applications rather than stainless steel or heavy metal for metal stickers or car emblems. If you are unsure what material to choose, your manufacturer can send samples or help you figure out exactly which is the best for you.

Material Types:

- Aluminum

- Brass

- Stainless Steel

- Polyester

- Vinyl

- Lexan

- Magnetic

- Static Cling

- Security (VOID)

- Reflective

Lamination

If you want your decals to be more durable, you have the option for lamination. By adding a layer of laminate on top, the design can sustain greater amounts of wear and tear before showing signs of usage.

There are different types of laminate for different situations as well. For example, if you are looking for a glossy finish, you can get a laminate that adds a layer of gloss while also protecting the design. Security laminates can leave a “VOID” marking upon a surface if they are removed (perfect for asset tags or warranty stickers). Certain laminates are better suited for weather, chemicals, or even paint. In short, it comes down to your situation and what you need.

Laminate will also be at an additional cost – something to have in the back of your mind when figuring out your tag solutions. However, this can be a fair trade-off for the extra durability it provides.

Customization

If you need total customization, decals are a fantastic option. They can be created using any image, cut to any shape, and use a variety of colors. Lettering decals can be made to fit into specific placements as well and can even include serialized (sequential) information and barcodes if necessary.

Printed decals can be die-cut to any shape you need. Most decals are standard shapes such as rectangles or ovals. If you want a badge decal to be specially cut to the outlines of a logo, for example, it can be done. If you need a clear section in part of the decal while the rest in color, that’s doable as well.

The printing process allows for sequential data, but variable data can be very costly.

This is where decals stand out from other tags.

Adhesives

Think of decals like custom stickers, but for industrial use. There a variety of vinyl decal sticker adhesives available, with different levels of strength. They range from general-purpose up to incredibly strong industrial-grade adhesive.

Sometimes it can be difficult to know if an adhesive will work for you unless you can test it out yourself. We can send sample products to you for you to try and see if it’s the right one. If you do receive a sample, make sure you are patient – adhesives can take 24 to 48 hours before they are fully settled.

We can guide you to which adhesive works best for you based on the application and conditions in which you plan to use the decal.

Color

What makes decals stand out from other solutions is the ability for full-color designs.

With other solutions, you are often confined to a single color. For example, anodized aluminum tags or chrome are typically confined to one solid hue.

The opposite is the case for decals. You can have as many colors as you want. You have the freedom to create a decal with vivid colors, which can not only look great but serve practical functions as well. Need a bold colored warning label that people won’t miss? A multi-color company logo?

It’s all possible with custom decals. Any image, any color, any design. Some applications require signs with color, such as GHS labels.

The Metal Marker Advantage

We work with you closely to deliver high-quality tags that fulfill your expectations. And we’re honest when something is infeasible or impractical. We’ll propose an alternative solution that satisfies your requirements, budget, and timeline.